LED Numeric Modules Deliver Quick Response for Car Interior Controls

Industry Background and Market Demand

The automotive industry is undergoing a rapid transformation, driven by advancements in digital interfaces and user experience. As vehicles become more connected and automated, interior controls must provide faster, more intuitive feedback to drivers. LED numeric modules have emerged as a critical component in modern dashboards, climate control panels, and infotainment systems, offering high visibility, low power consumption, and rapid response times.

Market demand is fueled by stricter safety regulations and consumer expectations for seamless interaction. Unlike traditional incandescent or vacuum fluorescent displays (VFDs), LED numeric modules ensure readability under varying lighting conditions while minimizing driver distraction. Automakers increasingly prioritize these modules for their durability and energy efficiency, particularly in electric vehicles (EVs), where power optimization is crucial.

Core Technology and Functionality

LED numeric modules are segmented displays that use light-emitting diodes (LEDs) to form digits, symbols, or simple alphanumeric characters. Their operation relies on semiconductor technology, where electrical current excites electrons in the diode, producing visible light. Key advantages include:

- High Brightness and Contrast – Ensures visibility in direct sunlight or low-light conditions.

- Low Power Consumption – Critical for EVs and hybrid vehicles.

- Fast Switching Speed – Enables real-time updates for speedometers, gear indicators, and HVAC controls.

- Long Lifespan – Typically exceeds 50,000 hours, reducing replacement needs.

These modules are often integrated with microcontrollers or driver ICs that manage input signals, ensuring synchronization with vehicle systems.

Product Structure, Materials, and Manufacturing

A typical LED numeric module consists of:

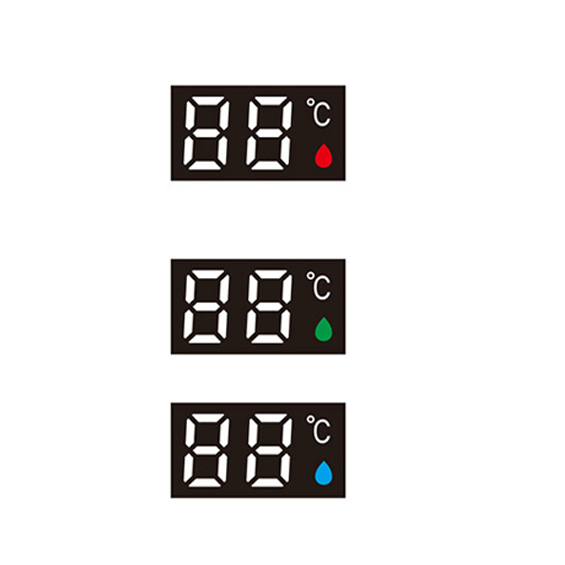

1. LED Chips – Made from gallium arsenide (GaAs) or gallium nitride (GaN), emitting red, green, blue, or white light.

2. Segmented Displays – Seven-segment or 14-segment layouts for numeric and limited alphanumeric output.

3. Encapsulation – Epoxy resin or silicone protects the diodes from moisture, vibration, and thermal stress.

4. PCB Substrate – Provides electrical connections and heat dissipation.

5. Diffuser Layers – Enhance light uniformity and reduce glare.

Manufacturing involves precision die-bonding, wire bonding, and encapsulation to ensure reliability under automotive-grade conditions (e.g., -40°C to 85°C). Surface-mount technology (SMT) is commonly used for compact, high-density designs.

Key Factors Affecting Performance and Quality

Several variables determine the effectiveness of LED numeric modules in automotive applications:

- Thermal Management – Excessive heat degrades LED efficiency; heat sinks or thermally conductive substrates mitigate this.

- Optical Design – Lens curvature and diffuser materials impact readability and viewing angles.

- Electrical Stability – Voltage fluctuations can cause flickering; robust driver circuits prevent inconsistencies.

- Environmental Resistance – Modules must withstand humidity, dust, and mechanical shock (tested per ISO 16750).

- EMI Shielding – Prevents interference with other vehicle electronics.

Supplier Selection and Supply Chain Considerations

Automotive manufacturers require suppliers to meet stringent quality standards, including:

- IATF 16949 Certification – Ensures compliance with automotive quality management systems.

- AEC-Q102 Qualification – Validates reliability under automotive environmental stress.

- Traceability and Scalability – Suppliers must provide full component traceability and support high-volume production.

Leading suppliers often collaborate with automakers early in the design phase to optimize module integration.

Common Challenges and Industry Pain Points

Despite their advantages, LED numeric modules face several challenges:

- Cost Sensitivity – High-quality materials and manufacturing processes increase expenses.

- Heat Dissipation in Compact Designs – Smaller modules struggle with thermal buildup.

- Compatibility with Legacy Systems – Retrofitting older vehicle architectures may require additional circuitry.

- Color Consistency – Variations in LED batches can lead to uneven displays.

Applications and Industry Use Cases

LED numeric modules are widely used in:

- Instrument Clusters – Speed, RPM, and fuel level displays.

- Climate Control Panels – Temperature and fan speed indicators.

- Infotainment Systems – Radio frequency and clock displays.

- EV Battery Status Indicators – State-of-charge (SOC) and range estimates.

For example, a luxury EV manufacturer recently adopted custom-designed LED modules with adaptive brightness, ensuring optimal visibility without distracting the driver.

Current Trends and Future Developments

The industry is moving toward:

- Higher Resolution and Customization – Dot-matrix LED displays for more detailed graphics.

- Integration with HMI Systems – Touch-sensitive or gesture-controlled feedback.

- Energy-Efficient Designs – Lower-power LEDs for extended EV range.

- Augmented Reality (AR) Overlays – Combining digital and physical displays for enhanced interactivity.

FAQ

Q: How do LED numeric modules compare to OLEDs in automotive applications?

A: LEDs offer higher brightness and longer lifespan, while OLEDs provide better contrast and flexibility. LEDs remain dominant for critical readouts due to reliability.

Q: Can LED modules be dimmed for night driving?

A: Yes, most modules support PWM (pulse-width modulation) dimming to reduce glare.

Q: What is the typical failure mode of LED numeric displays?

A: Gradual brightness reduction (lumen depreciation) or segment failure due to thermal stress.

Q: Are there any emerging alternatives to LED numeric modules?

A: Micro-LEDs and laser-based displays are under development but remain cost-prohibitive for mass adoption.

Conclusion

LED numeric modules are a cornerstone of modern automotive interior controls, balancing performance, durability, and energy efficiency. As vehicle interfaces evolve, these components will continue to play a pivotal role in delivering quick, reliable feedback to drivers. Manufacturers must focus on thermal management, optical optimization, and supply chain resilience to meet growing demands. Future advancements in customization and integration with advanced HMI systems will further solidify their position in next-generation vehicles.

286315373@qq.com

286315373@qq.com +86 18811889973

+86 18811889973

Phone

Phone

Comment

(0)