LED Numeric Indicators Enhance the Quality of Electronic Measurement Tools

Industry Background and Market Demand

The electronics manufacturing sector increasingly relies on precise measurement tools to ensure product reliability and compliance with international standards. As industrial automation expands, the demand for high-visibility, low-power numeric displays in multimeters, oscilloscopes, and calibration devices has grown significantly. LED numeric indicators, known for their durability and clarity, have become a critical component in modern measurement instruments.

Market research indicates a shift toward energy-efficient and high-contrast displays, particularly in environments with variable lighting conditions. Manufacturers prioritize LED-based solutions over traditional LCDs due to their superior brightness, longer lifespan, and resistance to temperature fluctuations.

Core Technology: How LED Numeric Indicators Work

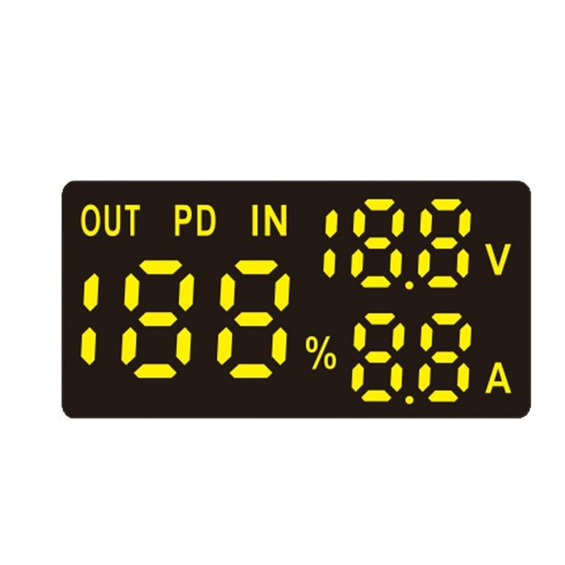

LED numeric indicators consist of segmented light-emitting diodes arranged to form digits (typically 7-segment or 14-segment displays). Each segment is individually controlled, allowing precise numerical representation. Key advantages include:

- High Visibility – LEDs emit their own light, ensuring readability in low-light or high-glare conditions.

- Low Power Consumption – Modern LEDs operate efficiently, reducing energy demands in portable measurement tools.

- Fast Response Time – Unlike LCDs, LEDs refresh instantly, critical for real-time data acquisition.

Advanced variants incorporate multiplexing techniques to reduce wiring complexity while maintaining display accuracy.

Design and Manufacturing Considerations

Materials and Construction

High-quality LED numeric indicators use:

- Gallium Arsenide Phosphide (GaAsP) or Gallium Phosphide (GaP) LEDs – Provide optimal brightness and color contrast.

- Epoxy Encapsulation – Protects against moisture, dust, and mechanical stress.

- Anti-Reflective Coatings – Minimize glare in outdoor or high-ambient-light applications.

Manufacturing Processes

Precision assembly ensures uniform segment alignment, while automated testing verifies brightness consistency and electrical performance. Manufacturers adhere to IPC-A-610 standards for solder joint reliability.

Key Factors Affecting Performance

1. Brightness Uniformity – Inconsistent LED segments can distort readability.

2. Viewing Angle – Wide-angle designs (≥120°) improve visibility in multi-user environments.

3. Power Efficiency – Low-voltage operation (2–5V) extends battery life in handheld devices.

4. Thermal Management – Heat dissipation impacts longevity, especially in high-duty-cycle applications.

Supplier Selection Criteria

When sourcing LED numeric indicators, engineers evaluate:

- Compliance with RoHS and REACH regulations

- MTBF (Mean Time Between Failures) ratings

- Customization options (digit height, color, interface protocols)

- Traceability and quality certifications (ISO 9001, IATF 16949 for automotive applications)

Industry Challenges and Common Issues

1. Compatibility with Legacy Systems – Retrofitting older instruments may require voltage-level shifting.

2. Environmental Durability – Industrial settings demand IP65+ rated enclosures to resist contaminants.

3. Signal Interference – Poor shielding can introduce noise in sensitive measurement circuits.

Applications and Case Studies

Laboratory Equipment

High-precision benchtop multimeters integrate ultra-bright LED displays to minimize parallax errors during calibration.

Industrial Automation

Programmable logic controllers (PLCs) use ruggedized LED indicators for real-time monitoring in manufacturing lines.

Field Test Instruments

Portable oscilloscopes with sunlight-readable displays enable accurate measurements in outdoor environments.

Future Trends and Innovations

1. Smart Displays – Integration with IoT-enabled devices for remote diagnostics.

2. Flexible LED Arrays – Conformable displays for compact or curved instrument designs.

3. Energy Harvesting – Solar-assisted power systems for off-grid measurement tools.

FAQ

Q: Can LED numeric indicators replace LCDs in all applications?

A: While LEDs excel in brightness and durability, LCDs remain preferable for ultra-low-power applications where backlighting is unnecessary.

Q: How do temperature extremes affect LED performance?

A: High-quality LEDs operate between -40°C to +85°C, but prolonged exposure beyond rated limits may reduce lifespan.

Q: Are there industry-specific standards for LED displays in measurement tools?

A: Yes, IEC 61010-1 outlines safety and performance requirements for electrical test equipment.

By addressing these technical and operational factors, LED numeric indicators continue to elevate the precision and reliability of electronic measurement tools across industries.

286315373@qq.com

286315373@qq.com +86 18811889973

+86 18811889973

Phone

Phone

Comment

(0)