How LED Digital Screens Improve Diagnostics in Smart Appliances

Industry Background and Market Demand

The integration of smart appliances into modern households and commercial spaces has accelerated over the past decade. Consumers and businesses increasingly demand appliances that not only perform core functions efficiently but also provide real-time feedback and diagnostic capabilities. Traditional diagnostic methods, such as error codes displayed via small LCD panels or blinking lights, often fail to deliver clear, actionable information.

LED digital screens have emerged as a superior alternative, offering high-resolution displays capable of conveying detailed diagnostics, maintenance alerts, and even interactive troubleshooting guides. According to industry reports, the global smart appliance market is projected to grow at a CAGR of 12.4% from 2023 to 2030, with diagnostic functionality being a key differentiator for manufacturers.

Core Technology: LED Digital Screens in Diagnostics

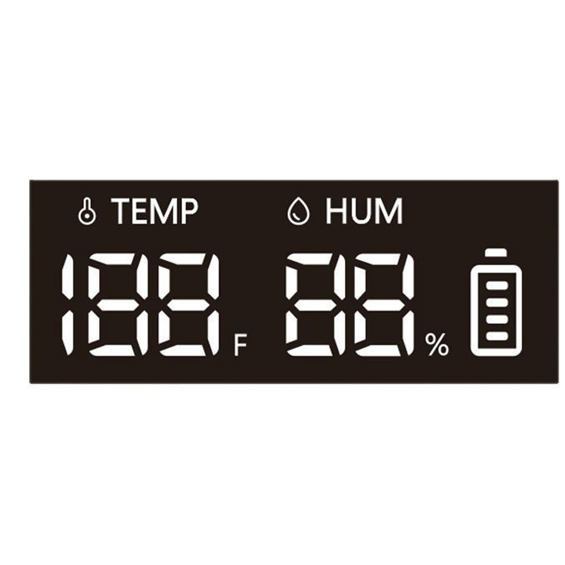

LED digital screens enhance diagnostics in smart appliances through several key features:

- High Visibility and Clarity: Unlike monochromatic LCDs, LED screens provide bright, high-contrast visuals that remain readable under varying lighting conditions.

- Dynamic Content Display: They support real-time updates, allowing appliances to show step-by-step troubleshooting, performance metrics, or firmware update notifications.

- Energy Efficiency: Modern LED backlighting consumes minimal power, making them ideal for always-on diagnostic displays.

These screens are often paired with embedded sensors and IoT connectivity, enabling appliances to self-diagnose issues such as motor failures, temperature fluctuations, or filter blockages.

Product Structure and Manufacturing Considerations

A typical LED digital screen module for smart appliances consists of:

- Display Panel: High-resolution LED matrix with adjustable brightness.

- Driver Circuitry: Ensures stable voltage supply and signal processing.

- Interface Board: Connects to the appliance’s main control unit via protocols like I2C or SPI.

- Protective Layer: Tempered glass or polycarbonate coating to resist scratches and moisture.

Manufacturers prioritize materials that balance durability and cost-effectiveness. For example, industrial-grade LEDs with a lifespan of 50,000+ hours are standard, while the housing often uses flame-retardant plastics to meet safety regulations.

Key Factors Affecting Performance

Several variables influence the effectiveness of LED screens in diagnostic applications:

1. Refresh Rate and Latency: Slow refresh rates can delay critical error alerts.

2. Environmental Resilience: Screens must operate reliably in high humidity (e.g., dishwashers) or extreme temperatures (e.g., ovens).

3. Software Integration: The display’s firmware must seamlessly sync with the appliance’s diagnostic algorithms.

Suppliers addressing these challenges gain a competitive edge in the B2B appliance components market.

Supplier Selection Criteria

When sourcing LED digital screens, manufacturers evaluate:

- Certifications: Compliance with UL, CE, or RoHS standards.

- Customization Capabilities: Ability to tailor screen size, resolution, and touch functionality.

- Supply Chain Reliability: Consistent lead times and post-sales technical support.

Top-tier suppliers often provide pre-certified modules, reducing time-to-market for appliance brands.

Common Challenges and Industry Pain Points

Despite their advantages, LED diagnostic screens face hurdles:

- Cost Sensitivity: Budget constraints in mid-range appliances may limit adoption.

- Interference Risks: Electromagnetic noise from motors or compressors can disrupt display signals.

- User Interface Design: Overly complex menus may frustrate end-users.

To mitigate these issues, some manufacturers adopt hybrid systems, combining LED screens with simpler indicator lights for basic alerts.

Real-World Applications

1. Refrigerators: Display energy usage trends and alert users to door seal leaks.

2. Washing Machines: Show real-time cycle progress and diagnose drainage issues.

3. Commercial Coffee Makers: Provide maintenance reminders and water hardness alerts.

A case study from a European appliance brand revealed a 30% reduction in service calls after implementing interactive LED diagnostics.

Current Trends and Future Outlook

The next wave of innovation includes:

- Augmented Reality (AR) Overlays: Users point a smartphone at the screen to access 3D repair guides.

- Predictive Diagnostics: AI-driven analytics (processed locally) forecast component failures before they occur.

- Modular Displays: Swappable screen units to extend product lifespans.

As smart appliances evolve into centralized home automation hubs, LED screens will likely serve dual purposes—diagnostics and control interfaces.

FAQ

Q: Can LED screens withstand steam in kitchen appliances?

A: Yes, with proper IP-rated sealing, they resist moisture ingress.

Q: How do LED diagnostics reduce warranty costs?

A: Clear error descriptions empower users to resolve minor issues without technician visits.

Q: Are touchscreens replacing button-based diagnostic panels?

A: Partially—touch is growing in premium models, but tactile buttons remain for reliability in harsh environments.

By addressing technical, economic, and usability factors, LED digital screens are redefining diagnostics in smart appliances—a trend poised to expand as connectivity and display technologies advance.

286315373@qq.com

286315373@qq.com +86 18811889973

+86 18811889973

Phone

Phone

Comment

(0)